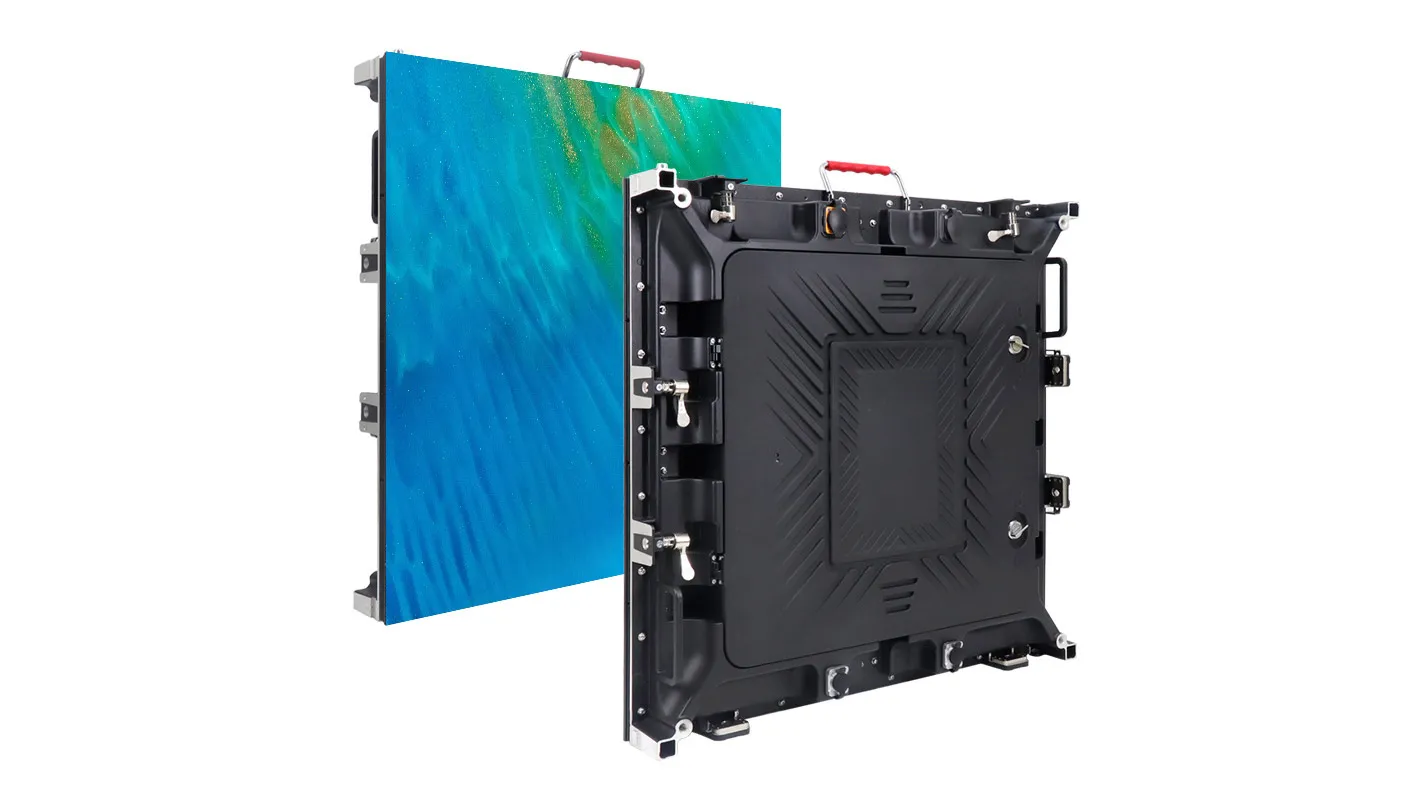

Let’s be blunt: in the lighting industry, a minor oversight in specification can derail a multi-million dollar project. Consider this—a 2023 report from LED Benchmark revealed that over 40% of product returns for high-end digital displays were due to inconsistent color, a problem directly traceable to poorly managed LED wavelength bins. That’s a staggering amount of wasted time, capital, and brand equity.

This isn’t just about buying components; it’s about engineering an experience. The light from an LED defines whether a medical treatment is effective, whether a crop yield is bountiful, or whether a brand’s signature red looks identical on every screen in a global campaign. And the absolute, non-negotiable core of that precision? It’s the science of LED wavelength.

Forget the dry, academic deep dive. Addressing the project manager, the engineer, and the savvy purchaser, this guide is specifically designed for you to understand the science of nanometers, color bins, and different key LED wavelengths, along with their practical applications, to be confident about your project’s requirements. At the conclusion, you will know not only what LED wavelength is, but also why it is your most effective tool for guaranteeing performance, quality, and consistency in any project involving LEDs.

1. What is LED Wavelength? It’s More Than Just Color

Take a common example of a pebble dropped in a water, and it will cause ripples or waves. The distance between these two waves is called the wavelength. This distance between two waves is so small that it is measured in nanometers (nm).

LED wavelength is the specific color of light that an LED emits, and this one number, measured in nanometers, determines the color our eyes perceive.

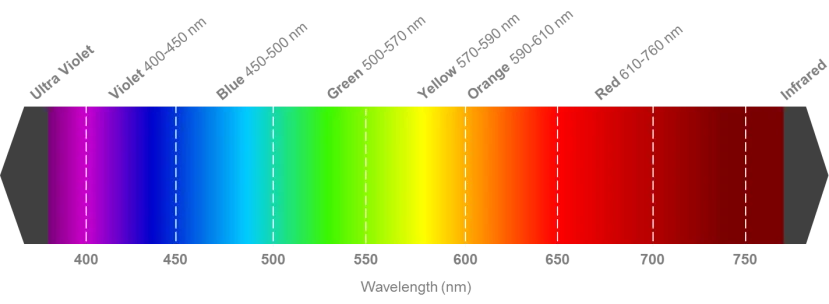

There are different LED wavelengths, each with its own characteristics and applications.

Here’s the crucial takeaway:

- Shorter wavelength ranges around 400-495nm and are high-energy blues and violets.

- Longer wavelength ranges around 620-750nm, and are lower-energy reds and ambers.

Every shade in the spectrum fits neatly on this scale. So, specifying a 625nm LED isn’t just a technicality—it’s a precise declaration of the exact red you will get.

2. Key LED Wavelengths & Their Applications

Understanding the significance and uses of each LED wavelength is key to selecting the right LED wavelength for your requirements. There is one electromagnetic spectrum producing LED wavelengths. It has two main types of regions: visible and invisible.

1. The Visible spectrum contains the wavelengths we see as color.

- Primary colors RGB

- Secondary colors

2. The invisible region contains:

- Infra red

- Ultra violet

2.1 Red LED Wavelength (~620-750 nm): The Efficiency King

RGB are the primary colors for creating light, based on human vision.

- Red

- Green

- Blue

The standard bright red LED wavelength falls between 620nm and 635nm. They are famously efficient, converting more power into visible light than heat. This makes them effective for large-scale outdoor displays where power bills and thermal management are major operational concerns.

Beyond display functions, a specific 660nm red is the workhorse of horticultural lighting, triggering photosynthesis and flowering in commercial greenhouse operations.

2.2 Blue LED Wavelength (~450-495 nm): The Modern Marvel

The blue LED wavelength falls between 450 to 465 nanometers and holds a remarkable importance due to the Nobel Prize won by its creators in 2014. What made it so significant?

- The Key to White Light: It’s the engine behind every phosphor-converted white LED on the market. Blue LEDs are the engine behind most modern white LEDs. They are used to excite a phosphor coating inside the LED package, which then glows yellow. The combination of blue and yellow light creates white light.

- Dynamic Displays: Blue is the primary color in the RGB color kit. Hence, the shorter blue wavelength produced cyan and rich purple colors on the LED

Other Uses: Beyond LEDs, blue wavelength power goes further. In industrial settings, high-energy 415nm blue light is used for UV-free curing of resins and inks in 3D printing and dentistry, slashing process times from hours to seconds.

2.3 Green LED Wavelength (~495-570 nm): The Sensitivity Superstar

There is a unique relationship between green light and the human eye. Green lights ranges approximately 455nm are automatically attracted by our visual system.

Perceived Brightness: Even while operating on the same power output, a green LED wavelength will look brighter to the human eye than a red or blue LED wavelength.

Color Gamut Anchor: Green is the crucial component of the RGB model. A precise and vibrant green is necessary to create a balanced and lifelike image. The quality of the green LED often dictates the overall color realism of a display.

The strategic implication? You can often use lower-power green LEDs to achieve high perceived brightness, directly optimizing the energy efficiency and total cost of ownership for a display.

2.4 Secondary Colors Wavelengths

These are the colors of the wavelengths that are derived from the combination of the primary colors RGB.

1. Yellow LED

A blue LED around 450nm is coated with a yellow phosphor. Some of the blue light is converted to yellow, and the human eye perceives the mixture as a solid yellow light.

Range: 575 to 595 nanometers

Primary uses:

- Traffic Signals & Warning Lights

- Automotive Lighting

- Display Backlighting

2. Orange LED

Ranges from 590 to 620 nanometers and is primarily used for:

- Construction & Road Work Signs

- Status indicators such as active or standby mode

3. Purple LED Wavelength

In reality, “purple” light is actually a blend of red and blue LEDs that are put closely together and appear purple to the human eye. It ranges from 370 to 410 nanometers.

Used For:

- Curing & Sterilization

- Black Light Effects

- Horticulture:

4. White LED: The Clever Illusion

A common misconception is that white has a wavelength. It does not. White is a mixture of different wavelengths. While light is produced with two methods:

- RGB Method: Combining individual Red, Green, and Blue LEDs very close. The human eye mixes the three colors to perceive white. This method allows for dynamic color tuning but can be more complex to control.

- Phosphor Conversion: The most common method—phosphor conversion—uses a blue LED chip (e.g., 450nm) to excite a yellow phosphor, creating a blend our brain interprets as white. The precise recipe of that phosphor mix determines the correlated color temperature (CCT), moving from warm to cool white.

2.5 UV and IR Wavelengths

The invisible spectrum is where some of the most innovative applications are born.

- Ultraviolet (UV) LEDs (100-400 nm): UVC LEDs in the 265-275nm range have become critical for germicidal applications in water and surface sterilization systems, a sector that saw explosive growth post-2020.

- Infrared (IR) LEDs (750nm-1mm): We can sense it as heat even though our eyes cannot see it. IR LEDs are used in night vision cameras and TV remote controllers.

3. Advanced Considerations: Where the Pros Live

You now understand the basics. But to truly master specification, you need to grasp a few advanced concepts.

3.1 Dominant vs. Peak Wavelength

These are not the same.

- Peak wavelength (λp) is the literal highest point on the SPD curve. The LED’s brightest light is emitted at this particular wavelength.

- Dominant wavelength (λd) is the perceived color. For LEDs with a broader spectrum, the dominant wavelength is the far more critical spec for visual applications.

Ignoring this difference is a common source of color mismatch.

3.2 The Voltage Connection

Here’s a practical tip for your engineering team: wavelength and forward voltage (Vf) are intrinsically linked. Shorter wavelengths (blues) require a higher forward voltage (3.0-3.6V) than longer wavelengths (reds, 1.8-2.2V). This isn’t trivia—it’s essential for designing efficient driver circuits and managing thermal load.

4. Critical Applications of LED Wavelength

In some fields, getting the wavelength wrong isn’t an inconvenience; it’s a failure.

4.1 LED Wavelength for Skin

The field of photobiomodulation is entirely built on precise LED wavelengths penetrating skin tissue to trigger biological responses.

- Acne-causing bacteria are efficiently targeted and destroyed by blue light at 415 nm.

- Red light in the 630-670nm range penetrates deeper, stimulating collagen production and reducing inflammation. For a device manufacturer, sourcing LEDs

4.2 Horticultural Lighting

Plants are sophisticated biochemical factories that respond to specific light signals—a science known as photomorphogenesis. Commercial growers don’t just use “white” light; they use precise recipes, or “light recipes”:

- 450nm blue for promoting compact, vegetative growth.

- 660nm red to trigger flowering and fruit production.

The ROI for a vertical farm hinges on the precision of these LED wavelengths to optimize growth cycles and maximize yield.

5. How does an LED create a Specific Wavelength?

It all comes down to a quantum process called electroluminescence.

There are two kinds of semiconductor material found inside an LED chip:

- n-type, which has an excess of electrons.

- p-type, which has an excess of “holes” that are waiting for electrons.

The point at which these two components intersect or meet is called a p-n junction. To energize the system, you need to apply the voltage on this junction, and the holes in the p-type are filled with electrons. However, they have to release energy to cross the intersection. One characteristic of the semiconductor material that determines how much energy it loses is called the “band gap.”

- The photon’s energy is determined by the size of the band gap.

- Additionally, the photon’s wavelength is determined by its energy.

6. The LED Wavelength Formula

The precise LED wavelength formula is derived from the physics of the band gap:

λ (nm) = 1240 / E (eV)

Where:

- λ is the wavelength in nanometers.

- E is the energy of the band gap in electron volts.

This formula shows the inverse relationship perfectly.

The larger the band gap is, the more energy an electron loses when moving across the LED’s p-n junction, resulting in a higher-energy photon (light particle) and a shorter wavelength.

This is why material science is everything. Manufacturers don’t use one magic material for all colors. They select specific compounds to target exact wavelengths:

- Indium Gallium Nitride (InGaN): The workhorse for shorter wavelengths: blue, green, and the blue pumps for white LEDs.

- AlGaInP, or aluminum gallium indium phosphate, is the preferred material for longer wavelengths, such as red, orange, and yellow.

This precise engineering is what makes modern LED technology so powerful and reliable.

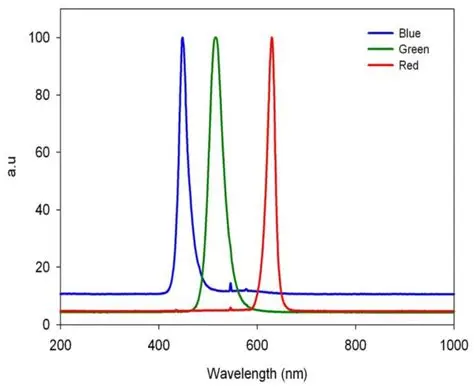

7. The LED Wavelength Chart (SPD)

If wavelength is the DNA, then the Spectral Power Distribution (SPD) chart is the full genetic report. For a B2B professional, this graph is far more valuable than any marketing claim. It plots the intensity of light across all wavelengths, providing an unforgivingly honest look at an LED’s output.

Learning to read an SPD chart is a critical skill.

- The x-axis shows LED wavelength (in nm),

- The y-axis shows relative intensity.

- A pure color LED shows a sharp, narrow peak.

- A white LED shows a broader curve, revealing the mix of blue and yellow phosphor-converted light.

7.1 Why LED Wavelength Chart a key?

- Precision: Move beyond subjective color names to objective, measurable standards.

- Consistency: Understanding Color Binning: No manufacturing process is perfect. There are natural variations from one LED batch to another. LEDs are tested by manufacturers and sorted into “bins” according to their particular wavelength and intensity. A wavelength chart visually defines these bins, showing the acceptable range of variation.

- Problem-Solving: Identify risks like metamerism, where two lights match under one source but clash under another, by comparing their underlying SPDs.

8. How to Choose the Right LED Wavelength: A Practical Checklist

- Define the Primary Goal: Visual appeal? Biological impact? Chemical reaction? The goal dictates the required precision.

- Examine the diagram from CIE 1931: Determine the relevant dominant wavelength by first locating the desired color coordinates on this industry-standard graphic.

- Demand Full Datasheets: Do not accept a spec sheet without a detailed SPD chart. Analyze it.

- Interrogate the Binning Strategy: Ask potential suppliers for their binning charts. Specify the tightest bin your project can afford. A wider bin is a wider risk.

- Consider Operational Stability: Understand how drive current and temperature might cause wavelength shift in your application. High-quality suppliers provide this data.

- Partner, Don’t Just Purchase: The most successful projects are built on partnerships with technical LED suppliers who can act as an extension of your engineering team.

9. FAQS

10. Conclusion

In the B2B world, knowledge is more than power—it’s profitability, performance, and risk mitigation. Understanding LED wavelength transforms a procurement decision from a cost-centric exercise into a strategic one. It empowers teams to specify for consistency, innovate with purpose, and optimize for efficiency and total cost of ownership.

It’s the difference between lighting that merely functions and lighting that performs brilliantly.

Ready to eliminate the risk of inconsistency and leverage light with precision? The technical team at EagerLEDscreens provides more than just components; we provide application-specific support, detailed spectral data, and tight binning strategies to ensure your vision is executed flawlessly.

Contact today for a confidential consultation on your project’s specific requirements.

Related Posts

Fill In Your Needs In Detail

Fill in the screen usage scene and size you need in “Content”.You will get a quote.