If you’re planning an event, visuals are everything. The LED packaging technology is a vital element that affects the overall visual experience. Today, the most common LED packaging technologies on the market are COB(Chip on Board), SMD(Surface-Mounted Device), and GOB(Glue on Board).

Each of these comes with its advantages. With the innovation in technology, MIP LED screen, as a next-gen solution, has gradually gained the favor of consumers in recent years. Therefore, an in-depth understanding of MIP LED knowledge is a crucial prerequisite for creating a wow event.

In this no-BS blog, we will delve into MIP technology, related packaging tech comparison, core advantages, price breakdown, installation and maintenance tips, and trend anticipations. Now, Let’s cut to it.

1. What is An MIP LED Screen?

Ok, let’s get started with the basics, since if you don’t know what a MIP LED Screen is, you may also be looking at a blank wall. So, what exactly is MIP LED?

MIP (Micro In Package) bonds microscopic LED chips onto a substrate first, seals them with epoxy, then fixes them onto screens. No exposed delicate bits!

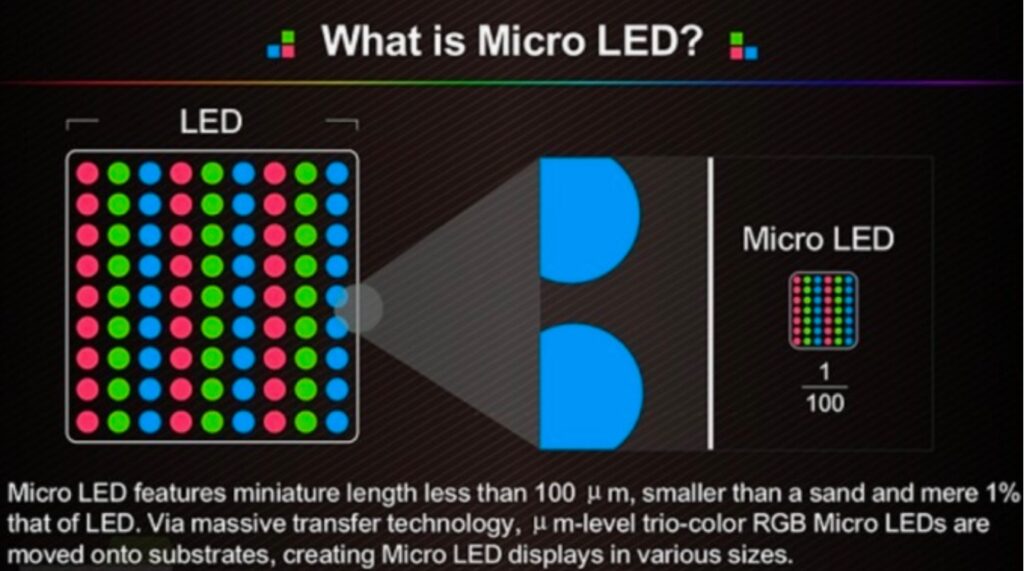

Wait…You may be confused about whether it is the same as a Micro LED display. The answer is No. Here’s the reason why they are different:

Micro LED Display: Each tiny LED(less than 100 micrometers) is mounted individually onto a substrate to provide ultra-high brightness and excellent color accuracy. It is difficult and costly to fabricate.

MiP LED Display: Bundles of Micro LEDs are pre-assembled into a single module that can be easily mounted onto a circuit board using the SMT process.

Key Takeaways:

- MIP LED is basically a Micro LED made easier and more practical.

- It keeps the image quality sharp, even for fine-pitch applications.

- If you want a jaw-dropping display without the insane price and headaches of traditional Micro LEDs, MIP LED Screens are your new best friend.

2. How Does MIP LED Technology Work?

What makes a MIP LED screen shine? Don’t worry. Next, we will explain the work principle from basic structure to concrete technology steps, ensuring you can comprehensively understand how it works.

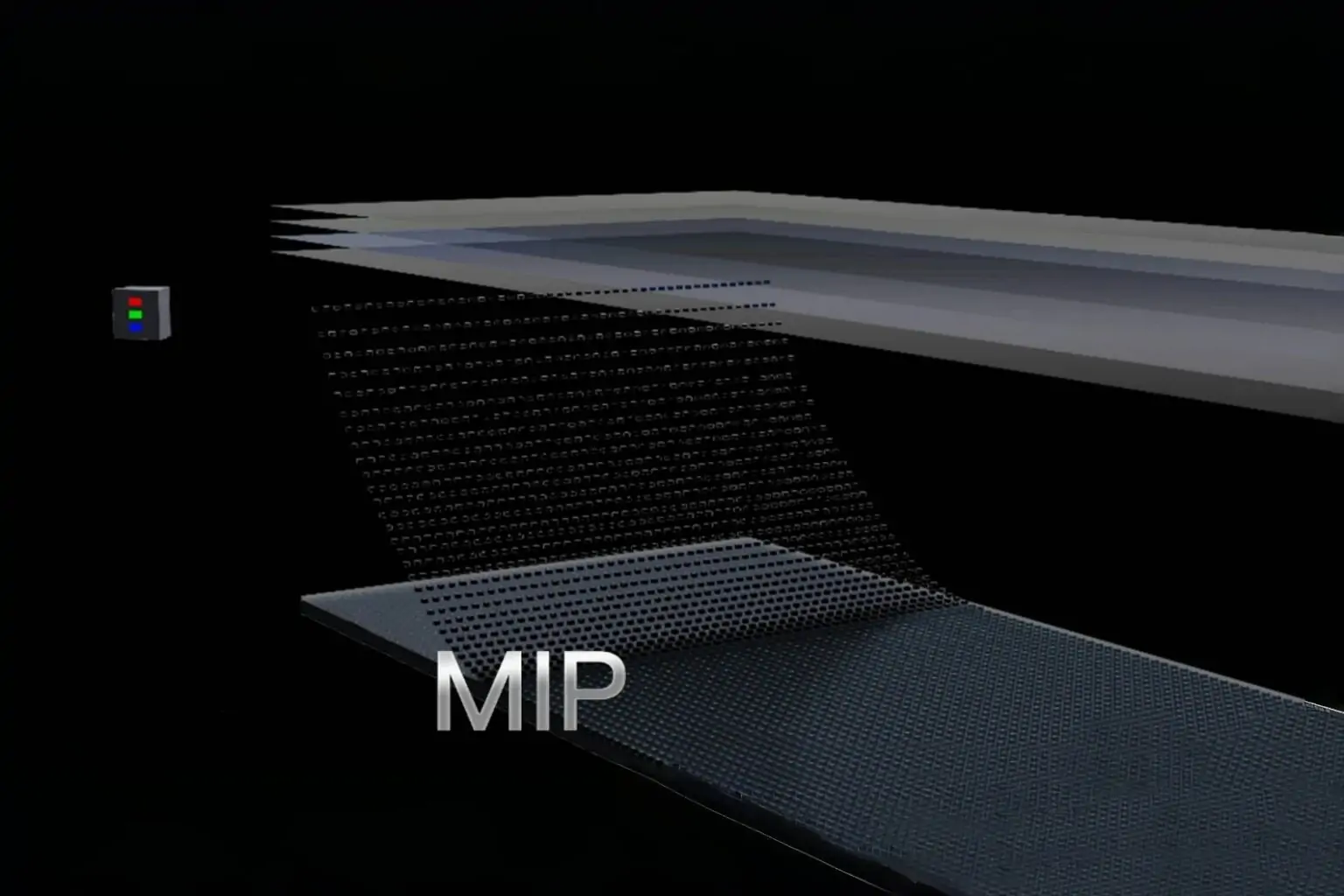

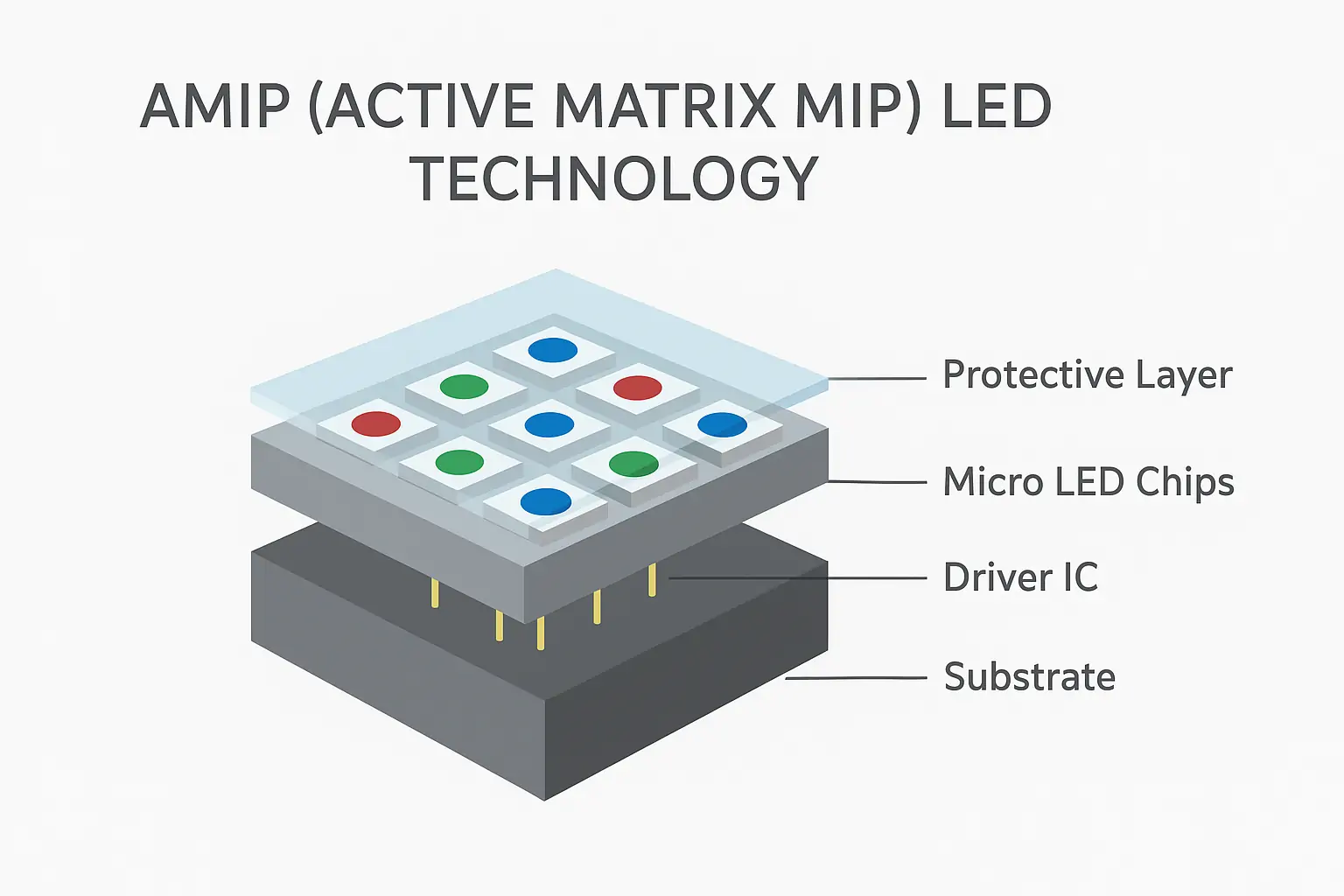

2.1 The Basic Structure of a MIP LED Module

- Micro LED Chips: They aretiny but mighty. Micro LED chips are the core light source that creates every color and image on your MIP LED s

- Substrate: Think of this as the basethat holds the micro LED chips or driver ICs in place and efficiently conducts heat.

- Protective Layer: A clear shield that guards the LEDs and driver ICs against dust, moisture, and everyday bumps, keeping your display safe and durable.

- Driver ICs: The brain of the LED module. For standard MiP, the driver ICs is an independent component on the PCB. However, it is integrated into the MiP package with the LED chips for AMiP(Advanced MiP).

- Power and Signal Cords: The lifeline that delivers electricity and data, ensuring every LED lights up at the right time with the right color.

- Solder Pads: Tiny connection points that link each LED chip to the substrate, enabling precise electrical flow and stable performance.

2.2 Step-by-Step MIP LED Technology Process

Here’s how MIP technology transforms signals into stunning visuals:

- Micro LED Chip Preparation:First, the ultra-tiny Micro LED chips are carefully crafted, diced, and Each LED chip is smaller than 100 micrometers.

- Chip-on-Board Assembly:Multiple LED chips are precisely placed onto a single board, boosting brightness, clarity, and overall display performance.

- Encapsulation:A protective resin layer is added over the LEDs, acting like a clear shield to guard against dust, moisture, and accidental knocks.

- Electrical Connection:Each chip is connected to the circuit through wire bonding or flip-chip technology so that power and signals can flow smoothly.

- MIP Modules Mounting on PCB:The finished MIP modules are securely mounted onto the PCB, ensuring they sit perfectly for long-term stability.

- Driver ICs Control MIP Modules:The driver ICs send commands to each LED cluster, telling them exactly when and how brightly to shine.

- Module Integration:Multiple modules are pieced together like puzzle tiles to create one seamless, jaw-dropping MIP LED Screen.

In short, MIP LED technology is a precise fusion of engineering and artistry. Every step – construction, assembly, protection, and control – collectively delivers a bright, durable, and flawless MIP LED screen that brings visuals to life with unparalleled clarity.

3. MIP LED vs COB LED vs SMP LED: Which is Better?

When it comes to LED display technology, you may hear a lot of two big names: COB LED and SMP LED. MIP LED as a new technology, do you know the difference between them? Let’s break them down to help you make the wise choice for your events.

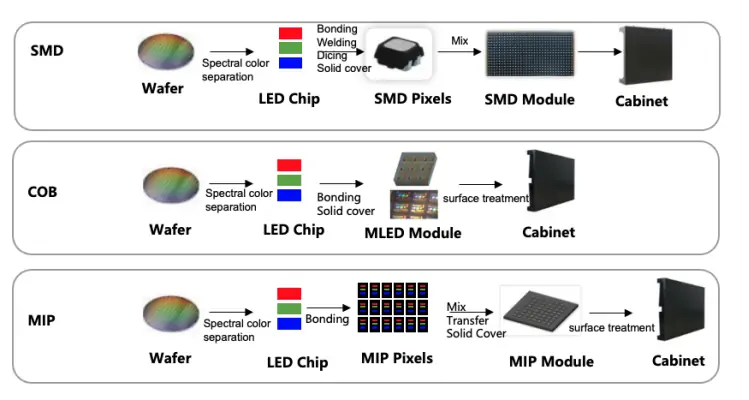

3.1 Definition & Technological Differences

1. MIP LED(Micro Integrated Package LED)

A packaging technology which incorporates multiple micro-LED chips into one pixel system. Provides outstanding durability, high visual performance, and better dust and moisture protection.

2. COB LED (Chip on Board)

The exposed LED chips are mounted directly on a PCB and then encapsulated in resin. This process creates a seamless, durable surface but they can be more sensitive to impact or surface damage.

3. SMP LED(Surface Mounted Device)

Individual LED chips are pre-packaged into small, standardized lamp beads and then soldered to the PCB surface. They are cost-effective and easy to maintain, but less suited for ultra-fine pixel pitch compared to MIP and COB.

3.2 Pros and Cons Comparison Between MIP LED, COB LED and SMP LED

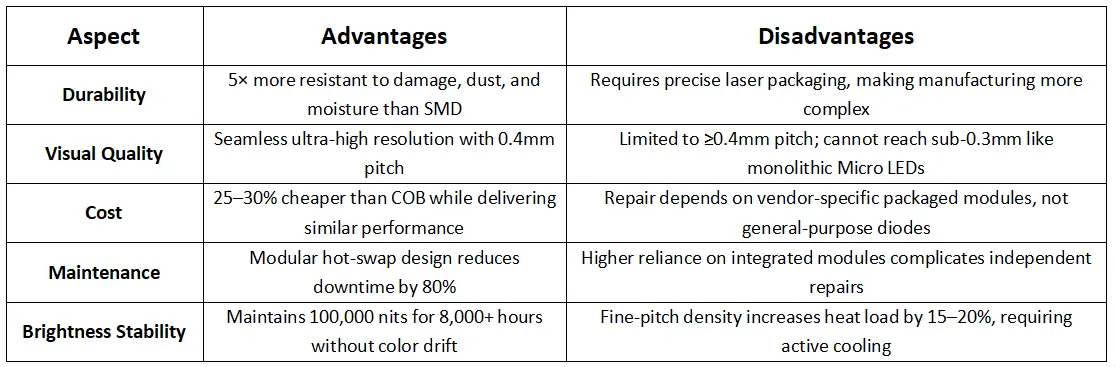

Each LED display technology has its own unique advantages for various applications. Here’s a clear pros and cons breakdown for MIP LED, COB LED, and GOB LED.

3.2.1 MIP LED

Advantages of MIP LED Technology:

- Superior Durability:Since the chip is encapsulated in epoxy resin before installation, MIP is 5 times more resistant to physical damage, moisture, and dust than SMD.

- Enhanced Visual Fidelity:As micro LEDs are pre-aligned in the package, the pixel gap disappears, allowing for ultra-high-resolution displays with a seamless pitch of 0.4mm.

- Cost-Effectiveness:Since MIP utilizes existing SMT assembly lines, its production costs are reduced by 25-30% compared to COB while performing comparable to COB.

- Simplified Maintenance:Thanks to its modular design, defective units can be hot-swapped in minutes without the need to remove the panel, reducing downtime by 80%.

- High Brightness Stability:By employing advanced heat dissipation technology in the package structure, MIP maintains 100,000 nits of brightness for 8,000+ hours without color drift.

Disadvantages of MIP LED Technology:

- Technical Complexity:Since packaging requires precise laser delivery, the manufacturing process requires tighter process control than SMD, raising the barrier to entry.

- Repair Dependency:Since the module integrates the packaged chip, vendor-specific components are required for repair instead of general-purpose diodes.

- Thermal Management:Active cooling is required due to the higher pixel density of fine-pitch configurations (<0.7mm), which increases the heat load by 15-20% compared to COB.

- Micro Pitch Limits:While MIP excels in 0.4-1.2mm pitch, it still can’t match the sub-0.3mm performance of monolithic Micro LEDs when it comes to nanodisplays.

3.2.2 COB LED

Pros of COB LED:

- Ultra-High Brightness: The display is bright enough to shine even in well-lit rooms.

- Excellent ColorConsistency: Colors are smooth and uniform with no spots.

- Seamless Appearance:The surface is flat and smooth, with no noticeable gaps between the LEDs.

- Good Heat Dissipation:It handles heat well and helps keep performance stable.

Cons of COB LED:

- Impact Resistance:Bumps or scratches can easily damage surfaces.

- Difficult to Repair:If one component fails, the entire component often needs to be replaced.

- Higher Price:You will pay more compared to the older LED packaging method.

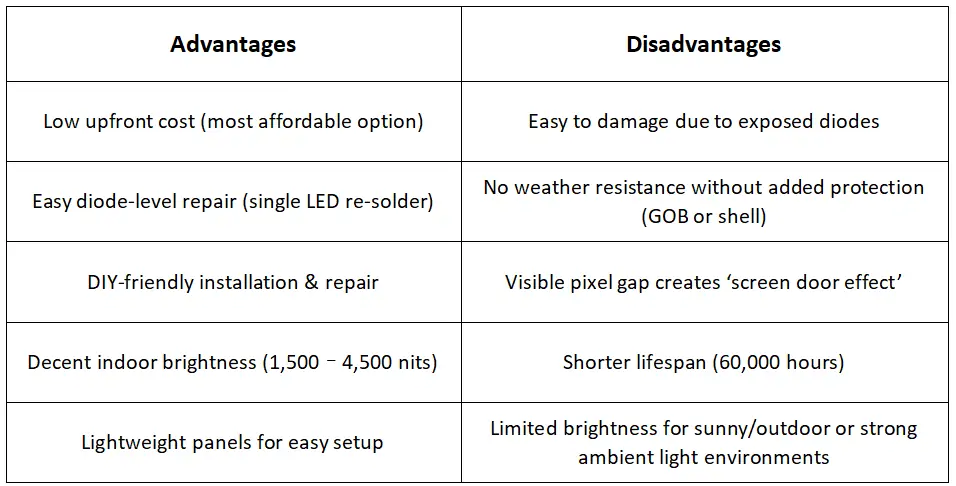

3.2.3 SMP LED

Pros of SMP LED:

- Low Upfront Cost:SMP’s simple design makes it the most affordable LED technology for basic displays.

- Easy Diode-Level Repair:A single faulty LED can be re-soldered (unlike COB/MIP modules), reducing long-term maintenance costs.

- Easy DIY:The standard SMT process allows local technicians to install or repair panels without vendor certification.

- Decent Indoor Brightness:Provides 1,500-4,500 nits of brightness, which is enough for controlled lighting (meeting rooms, menus).

Cons of SMP LED:

- Easy to Damage:Exposed diodes can fail due to dust, moisture, or even light finger pressure.

- No Weather Resistance:Outdoor/wet environments require the addition of glue (GOB) or shell.

- Visible Pixel Gap:Large spacing (usually greater than 1.0 mm) creates a “shield door effect” when viewed up close.

- Shorter Lifespan:The average lifespan is 60,000 hours due to the fragility of components, compared to 100k+ hours for MIP/COB.

- Limited Brightness:Difficult to use in sunny spaces or places with strong ambient light (stages, storefronts).

- Lightweight Panels:Thinner and lighter than COB/MIP, simplifying ceiling installation or temporary setup.

3.3 When to Pick MIP LED, COB LED or SMP LED

- Choose MIP LED when you require fine-pitch indoor displays with a long lifespan.

- Pick COB LED when the main requirement is maximum brightness and color accuracy under safe conditions.

- Select SMP LED for cost-conscious applications where availability and maintenance are of primary importance.

MIP LED, COB LED, and SMP LED each have their strengths. The best pick hinges on your specific use case, budget, and performance goals. Pair the right tech with your projects, and your display will deliver a stunning visual effect.

4. 9 Key Features of MIP LED Screens You Must Know

To be honest, if you wanna to invest in MIP LED displays, you need to know why they’re worth the investment. Let’s keep going. You will know why it is an ideal solution for your events. Think of it as your cheat sheet to MIP LED technology greatness.

4.1 High Brightness

MIP LED screens are bright and dazzling, allowing your content to be clearly visible even on sunny days. Whether it’s in multiple lighting conditions, your visuals won’t fade.

4.2 Compatible with Multiple Substrates

MIP technology is compatible with a wide range of substrates, allowing for flexibility in design and fabrication. MIP LED technology adapts effortlessly to the environment, so your creative ideas aren’t limited by walls or frames.

4.3 Energy Efficiency

Running a MIP LED display won’t increase your electricity bill significantly. Thanks to clever MIP LED technology, it reduces power consumption without compromising brightness or performance. You’ll get a sustainable and eco-friendly display that will delight your audience and your wallet.

4.4 Excellent Heat Dissipation

MIP LED screens remain cool even when displays are in marathons. The heat spreads and releases can avoid overheating efficiently. Your screen is smooth operating, preserves its components and increases lifespan with MIP LED technology.

4.5 High Contrast Ratio

MIP LED displays deliver stunning deep blacks and vibrant colors, with contrast ratios typically exceeding 5,000:1 for indoor models and 10,000:1 or higher for premium panels. This high contrast ratio makes videos, images, and graphics pop as if they jumped out of the screen – even in bright environments.

4.6 Durability and Longevity

MIP LEDs have longevity. They are tough enough to withstand harsh conditions, such as dust, moisture, and even 100,000 working hours. With MIP LED technology, your screen is guaranteed to remain bright for more than 10 years.

4.7 Easier Maintenance

Maintaining your MIP LED screen is surprisingly straightforward. Thanks to front-accessible modules, most repairs or replacements can be completed in under 10 minutes per module. MIP technology is designed for convenience, minimizing downtime and keeping your screen running smoothly.

4.8 Cost-Effectiveness

The upfront investment in MIP LED displays may seem expensive, but long-term use can lead to cost savings. These displays consume as little as 250 watts per square meter and are also low maintenance, making them highly cost-effective. MIP LED screen ensures maximum ROI with long-lasting performance and low operating expenses.

4.9 Better Color Consistency

The colors of the MIP LED screen remain vibrant and uniform, with a color gamut covering 95% of the NTSC spectrum. Say goodbye to mottled or dull areas – delivering consistent brightness with every pixel. MIP LED technology ensures that your visuals remain accurate and eye-catching, whether on a bright sunny day or in a dimly lit indoor environment.

Therefore, understanding the MIP LED screen features can help you make a more informed choice. Each feature plays a crucial role in delivering a stunning visual experience, and you can comprehensively measure their value to ensure that your investment in MIP LED technology truly pays off.

5. Where Are Fine-Pitch MIP LED Walls Used?

In plain terms, the smaller the distance between the pixels, the sharper and clearer your image. If you can use MIP LED screens in the right places, they will maximize your business value and revenues. So, let’s talk about where these gorgeous fine-pitch MiP LED walls can be used?

Top Spots for Fine-Pitch MIP LED Screens:

1. Virtual Film Studios: MIP LED Video Walls with 8,000 nits brightness and 1,000,000:1 contrast create hyper-realistic backgrounds for films and TV shows. No more “uncanny valley” CGI – just seamless, immersive worlds that save studios millions in location costs.

2. Boss-Level Boardrooms: Tired of pixelated spreadsheets in meetings? MIP LED Screens (as fine as P0.6mm) turn conference rooms into mission control. Zero seams mean Excel grids stay perfectly aligned, and 170° viewing angles keep remote attendees from squinting.

3. Retail & Showroom: The retail stores or showrooms decked walls and ceilings with MIP LED screens, turning shoe displays into aurora borealis spectacles. Shoppers interact with AI-generated art while cameras track engagement.

4. Control Room: MIP LED Walls in control rooms visualize millions of data points (accidents, transit, weather) on seamless 20-foot displays. Operators spot gridlock in 4K clarity, while heat dissipation tech prevents meltdowns during emergencies.

5. Hospital’s Surgery: Surgeons use MIP LED screens to stream 4K endoscope feeds during operations. Color accuracy ensures they don’t confuse an artery with a burrito thread, while sterilization-friendly surfaces survive bleach scrubs.

6. Exhibition & Event Spaces: Big expos or conventions? No problem. Fine pixel pitch on an MIP LED Screen makes product demos, live streams, or interactive displays vibrant and immersive. People will stop in their tracks to watch.

The fine-pitch MiP LED displays in the suitable places are crucial to provide audiences with crisp images, clear messages, and immersive visual experience. You should take a deep consideration about whether they are a good fit in your events.

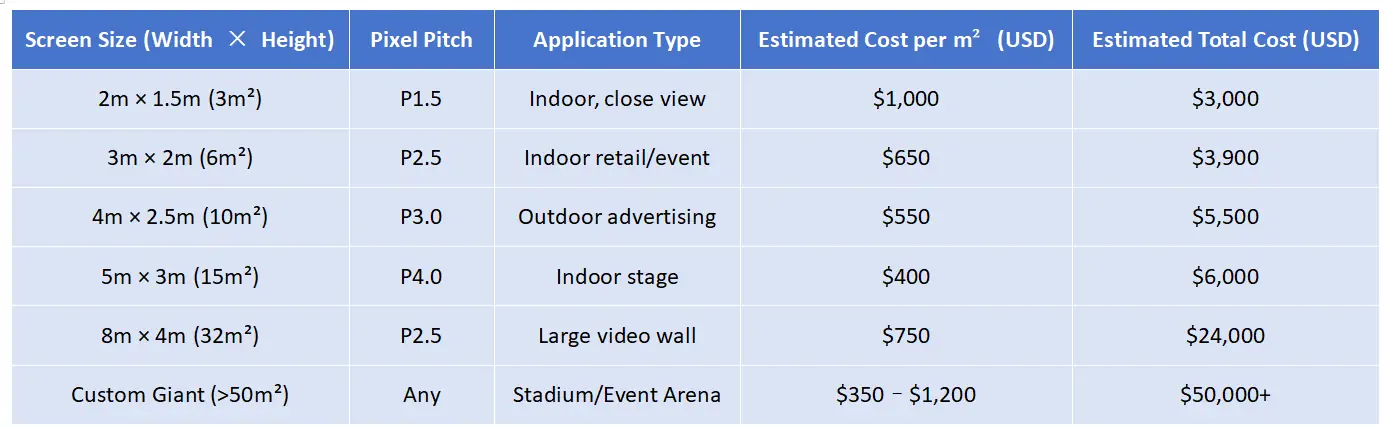

6. How Much Does MIP LED Display Cost?

To be frank, the price of a MIP LED screen is a bit like ordering pizza: the final cost depends on the size, specifications, and how fancy you want it to look.

6.1 Key Factors That Affect the Price

1. LED Chip Type: The cost of complex RGB Micro LEDs is higher than ordinary Micro LEDs because of more complicated manufacturing process.

2. AMiP Tech: AM-driven MIPs (Integrated Micro ICs) eliminate the vague “caterpillar effect” but increase costs by 10-15%. Mostly used on surgical screens or in Hollywood studios.

3. Pixel Pitch: The smaller the pitch, the sharper the image….and yes, the higher the price. It’s like going from economy to first class, and you’re paying for the view.

4. Brightness Levels: Need to fight sunlight? 8,000-nit MIP LED Screens cost 20% more than 5,000-nit models. Pro tip: Skip the ‘sun-slaying’tier for indoor boardrooms.

5. Screen Size: A pocket-sized MIP LED Screen costs less than a giant MIP LED Video Wall that covers your entire conference room.

6. Installation Method: Wall-mounted, hanging, or free-standing? Some setups need more hardware (and more coffee for the installers).

6.2 MIP LED Screen Cost Overview

Note: This is an estimated cost. The detailed cost information depends on your vendors.

The cost of a MIP LED screen is not just about the screen but what it can bring to your brand, event, or audience. In addition to factors mentioned above, screen shapes, smart functions, or manufacturers also will influence the price. So you should invest in something that makes your message impossible to ignore.

7. Future Trends in MIP LED Display Technology

If you think MIP LED screens are impressive now, buckle up—because the next wave of MIP LED technology is going to make today’s LED displays look like flip phones. Let’s talk about where this tech is headed.

7.1 Two Main Trends in MIP LED Display

1. Ultra-Fine Pixel Pitch Becomes Mainstream

Remember that fine pixel pitch is an advanced, exclusive feature? In the future, ultra-fine pixel pitch will become mainstream. This means that your MIP LED screen will not only look clear in a showroom but also in your living room, office, or even in the mirror in your bathroom (okay, maybe not, but you get what I mean).

2. New Applications Around Every Corner

As costs decrease and manufacturing levels increase, MIP LED technology will appear in places you never thought possible: curved art installations, large-scale AR/VR experiences, retail store windows that talk to you, and even wearable technology. The boundary between screen and environment? Disappeared.

7.2 Core Advancement in MIP LED Technology

AMiP, called active matrix IC & Micro LED in Package, stands for an important progress in Micro LED screen technology. Each micro-LED is driven by an active matrix circuit instead of simple passive wiring to ensure faster response times, finer brightness control, and lower power consumption.

Flexible or Class-Based Substrates: Can screens be bent, folded and shaped like origami? Of course. MIP LED displays can be mounted on curved walls, ceilings, or even rolling billboards. Meanwhile, the glass substrate supports ultra-thin, high-resolution designs for AR/VR and transparent displays.

Advanced LED Chips: Smaller, more powerful, and more efficient chips mean brighter, more vibrant images without consuming energy.

Transparent MIP Technology: You can see the display through it, perfect for futuristic-style store facades or car windshields. Why not turn the dashboard of your Tesla car into a full movie screen?

AI-Powered Smart Content: Your MIP LED screen will quickly decide what is best for your audience based on the time, mood, or people passing by. Give somebody the creeps? Maybe. Is it cool? Of course.

All in all, the future of MIP LED technology is bright. With ultra-fine pixel pitches, mind-bending flexibility, AI-driven content, and see-through displays, the only limit is our imagination. If you thought LEDs were just “screens,” get ready to see them redefine entire environments.

8. FAQs

9. Conclusion

To sum up, an MiP LED screen uses microscopic LED chips mounted on a substrate to create brighter, more energy-efficient LED displays. Compared to SMD and COB LEDs, MiP LEDs feature longer durability, more seamless pixel gaps, and a more affordable price.

With the evolution and development in recent years, MIP LED display will become a mainstream LED solution used in multiple scenarios such as shopping malls, brand conferences, LED volumes, and OOH advertising. We can say the future of LED is MiP. You can contact us to get your MIP LED screen quote today.

Related Posts

Fill In Your Needs In Detail

Fill in the screen usage scene and size you need in “Content”.You will get a quote.