COB Vs. GOB in LED display technologies, which one is better? Let’s find out! Choosing the best LED display is about more than simply brighter visuals. It’s also about performance, precision, and profitability. Considering these factors, LED technologies tend to improve day by day, with COB (Chip-on-Board) and GOB (Glue-on-Board) emerging as two leading solutions. Whether you are a business buyer or an advertiser, understanding these technologies is crucial for making long-term investments.

It’s time to make a business decision. Purchasing the incorrect display might cost thousands of dollars. Continue reading to find out which LED solution is the best value for your money.

This article will provide a comprehensive guide to both LED technologies, including how they work, pros and cons, applications, and a detailed comparison so that one can make an informed decision regarding LED selection for both industrial and commercial purposes.

- 1. Обзор светодиодного дисплея COB

- 2. Минусы и плюсы технологии COB-светодиодов

- 3. Для чего используется COB-светильник? Реальные применения

- 4. Обзор светодиодного дисплея GOB

- 5. Преимущества и недостатки светодиодного дисплея GOB?

- 6. Светодиоды GOB и их применение

- 7. COB или GOB: что лучше?

- 8. Как выбрать COB или GOB?

- 9. COB против GOB: ключевые соображения относительно конкретных требований

- 10. Анализ стоимости дисплеев COB и GOB:

- 11. Как найти надежных производителей светодиодных дисплеев?

- 12. Заключение

1. COB LED Display Overview

COB stands for “chip-on-board.” It is a form of LED technology that can produce high-resolution images for indoor displays. Compared to conventional LED displays, this design improves brightness, thermal efficiency, and dependability.

1.1 How Does COB LED Technology Work

A COB LED uses a technology in which several LED chips are combined beneath a consistent protective layer and put directly onto a single circuit board. A substrate, the base layer, is used for structural or thermal support on which the dense arrays of bare LED chips are placed directly.

These chips are connected electrically with the bonding wires, and then coated with phosphor for color conversion. Now the chips are encapsulated in silicone resin, and are being them with a heat sink, forming a compact, high-efficiency lighting module.

Below is the step-by-step procedure of how the COB LED module is structured:

1.1.1 Substrate (Base Layer)

It serves as the base, offering thermal conductivity and mechanical support to avoid overheating. Substrate is usually composed of metal-core PCB (MCPCB) or ceramic (AlO₃/AlN) for optimal heat dissipation.

1.1.2 LED Chips (Multiple Diodes in One)

The substrate is directly attached to dozens of bare LED chips, most of which are GaN-based.These LED Chips are tightly packed in circuits, either in series or parallel, to provide a high-density, gap-free light output.

1.1.3 Bonding Wire (Electrical Connection)

These are Gold or copper wires that connect the chips to the circuit, ensuring optimum current distribution.The Flip-Chip, a more advanced version of the COB, does away with wires for improved heat transmission and reliability.

1.1.4 Phosphor Coating

Phosphor coating acts as a color conversion layer containing yellow color. It is layered on the LED chips that convert blue color light into white light.

1.1.5 Encapsulation

To guard against moisture, dust, and physical damage, silicone or epoxy resin is used to seal each component.

1.1.6 Heat Sink Attachment (thermal interface)

To dissipate heat and extend longevity, the substrate is mounted atop an aluminum or copper heat sink.

2. Cons and Pros of COB LED Display Technology

2.1 Advantages of COB Technology

Think about the smooth, pixel-free visuals even when viewed up close. Discover the detailed benefits that COB technology offers.

- Compact Design: LED chips are directly placed into a single circuit board, hence saving space and eliminating the need for individual packaging.

- Lighting Consistency: The compact design (LEDs mounted directly on a single PCB) ensures smooth and uniform color distribution throughout the display.

- Energy Efficient: There is a direct thermal path that reduces heat dissipation as compared to traditional ones, while providing equivalent display with higher efficiency.

- Improved Resolution: COB LED display has high pixels, which means more and more LED chips can be packed per unit area. This leads to an improvement in overall brightness and resolution.

- High Durability: Sturdy construction guards against physical harm and vibration, providing high durability in COB LED technologies.

- Heat Dissipation: COB technology has a direct substrate connection with LED chips that decreases thermal resistance, hence improving heat dissipation.

- Improved Visual Quality: These LEDs eliminate pixelations and multi-shadow effects by putting bare LED chips directly onto the PCB without the need for plastic housings to provide a smooth, gap-free surface with consistent light distribution, thus providing clearer images.

- Better Viewing Angle: Unlike SMD LEDs, where the small lenses make colors look wrong when viewed from the side, COB LEDs provide consistent color and a wider 180°+ visibility from any angle because they don’t use plastic housing that blocks the light, unlike SMD LEDs

- High Reliability: They have an extended lifespan as a result of effective heat control. Their direct chip-to-board design transfers heat more quickly, avoiding damage. Better cooling means they may remain bright for years without burning out, unlike traditional LEDs.

2.2 Disadvantages of COB Technology

This is not your typical LED strip – It does have certain disadvantages, though.

- Repairing issues: As LEDs are mounted on a one circuit, the replacement of damaged LEDs may not be possible; hence, the entire module needs to be replaced in this case.

- Cost: COB LED displays use advanced manufacturing techniques, using premium materials and considering the thermal specifications. This process costs more than conventional LEDs.

3. What is COB light used for? Real Life Applications

From high-end film sets to corporate boardrooms, COB technology is revolutionizing visual display with clarity and precision. Here are some of its key applications:

1.Businesses and Retail Stores: Due to their smooth, uniform, and consistent color, COB LEDs are used for commercial and retail displays such as corporate lobbies, showrooms, etc.

2.Education & Corporate Spaces: COB LEDs have the capability of reducing eye strain, hence are best for long-duration viewing, such as boardrooms, lecture halls, and conference centers.

3.Virtual Production: They offer greater brightness, wide viewing angles, and natural color effects, making them ideal for TV studios, movie sets, and virtual production stages.

4.Control Rooms & Command Centers: High resolution, reliability, and consistent performance make them best for 24/7 operations in airports, traffic management, and security hubs.

5.Fine-Pitch Video Walls: COB LEDs have an ultra-HD pixel pitch, ensuring vibrant and sharp visuals that resemble real imagery. Hence, perfect for museums, luxury advertising, and other related high-resolution applications.

4. GOB LED Display Overview

GOB stands for “Glue on board.” It is a type of LED display used for outdoor displays and is created to enhance durability and reliability in harsh environmental conditions.

The main purpose of designing the GOB LED display was to ensure the durability of the display and provide resistance to any kind of physical impact, rain, or dust etc. While maintaining the smoothness of the overall display.

4.1 How does GOB Technology Work?

Glue on Board, or GOB, is a protective encapsulation technology that applies a unique transparent epoxy adhesive over the LED modules to increase the durability of LED displays. In contrast to COB (Chip on Board), which incorporates LED chips straight onto the PCB, GOB begins with conventional SMD (Surface-Mounted Device) LEDs and applies a protective coating to prevent environmental deterioration.

4.2 Structure of GOB LED Module

Below is a step-by-step procedure of how the GOB LED display is structured.

Standard SMD LED Assembly: Standard SMD (Surface-Mount Device) technology is used to initially mount the LED chips onto the PCB. Every LED is soldered into place and has its plastic casing.

Applying Epoxy Glue: Over the whole LED module, a high-transparency, thermally conductive epoxy glue is carefully applied. The glue covers LED chips, solder joints (preventing oxidation), and Circuitry (protecting against moisture and dust).

The Curing Procedure: The epoxy forms a strong, clear protective covering after being heat- or UV-cured. This layer resists water, scratches, and impacts.

Final Testing & Sealing: The display undergoes IP65/IP66 waterproof certification testing. For outdoor use, additional coatings may be applied for UV resistance.

5. Advantages and Disadvantages of GOB LED Display?

5.1 Advantages Of GOB LED Display

Built tough, GOB displays withstand rainstorms, loud concerts, and the chaos of busy retail environments. Here are a few of its core advantages.

- Durability & Enhanced Protection: Each component is layered with a protective conductive glue that enhances additional protection, hence improving durability.

- Improved Visuals: GOB technology minimizes the risk of light leakage between LED pixels, which improves the contrast and consistency of the colors throughout the display.

- Weather & Impact Resistance: The layer of glue acts as a resistance to outdoor environmental conditions. This stops UV degradation, corrosion, and physical damage.

- Easy Maintenance: The technology (SMD) used in GOB LEDs allows for the replacement or repair of the damaged part, hence providing optimal maintenance.

- Cost-effective: The GOB LEDs require less maintenance due to the epoxy glue layer, which makes it a cost-effective solution with optimal performance.

5.2 Disadvantages Of GOB LED Display

Overall, GOB LEDs are the best choice for outdoor displays, but they may have thicker modules that affect the overall thickness and weight of the display compared to other modules.

Warning: Low-quality glue = low-quality visuals. Choose wisely! .

One major concern GOB LED might encounter is that some manufacturer uses low-quality glue that will reduce the costs but affect over all display quality.

6. GOB LEDs & Their Applications

GOB LEDs are built to handle pressure—literally. Discover which types excel in various demanding environments.

6.1 Small Pitch GOB LED Displays

Traditional small pitch LEDs give sharp images but fail in humid or dusty conditions. GOB small pitch screens solve this by sealing pixels in protective epoxy, letting them work perfectly in indoor pools, luxury stores, and outdoor digital signage where regular displays would break down.

6.2 Rental GOB LED Screens

Normal rental LEDs stop working if rain or condensation gets inside. GOB rental screens fix this with their waterproof coating, making them perfect for outdoor concerts and festivals where the weather can change suddenly. They also survive hundreds of setups without damage.

6.3 Floor GOB LED Displays

Regularly walkable LEDs get damaged by spills and foot traffic. GOB floor screens solve this with a super-tough epoxy layer that protects against drinks, high heels, and dropped objects – ideal for museums and shopping malls where people walk on the display.

6.4 Transparent GOB LED Screens

Standard see-through LEDs get dirty between pixels and fade over time. Transparent GOB displays fix this by completely sealing the pixels, keeping them clean and bright for years in airport windows and store displays where clarity matters most.

6.5 Flexible GOB LED Panels

Basic flexible LEDs crack when bent or in temperature changes. GOB flexible screens solve this with special bendable epoxy that moves with the display, allowing durable curved installations in theme parks and modern building designs.

6.6 Irregular-Shaped GOB Displays

Custom-cut traditional LEDs have exposed edges that let in dust and moisture. Irregular GOB screens fix this by coating every edge perfectly, making creative shapes like circles and hexagons work reliably in art installations and architectural features.

By providing the solutions to traditional LED problems, while maintaining overall visual display, GOB stands out in terms of reliability, durability, and cost effectiveness. GOB technology defines the future of LED displays by providing performance where traditional solutions cannot, whether in high-traffic public areas, temporary event screens, or fixed outdoor installations.

7. COB Vs GOB: Which is Better?

Not sure whether COB or GOB is your match? Let’s go head-to-head.

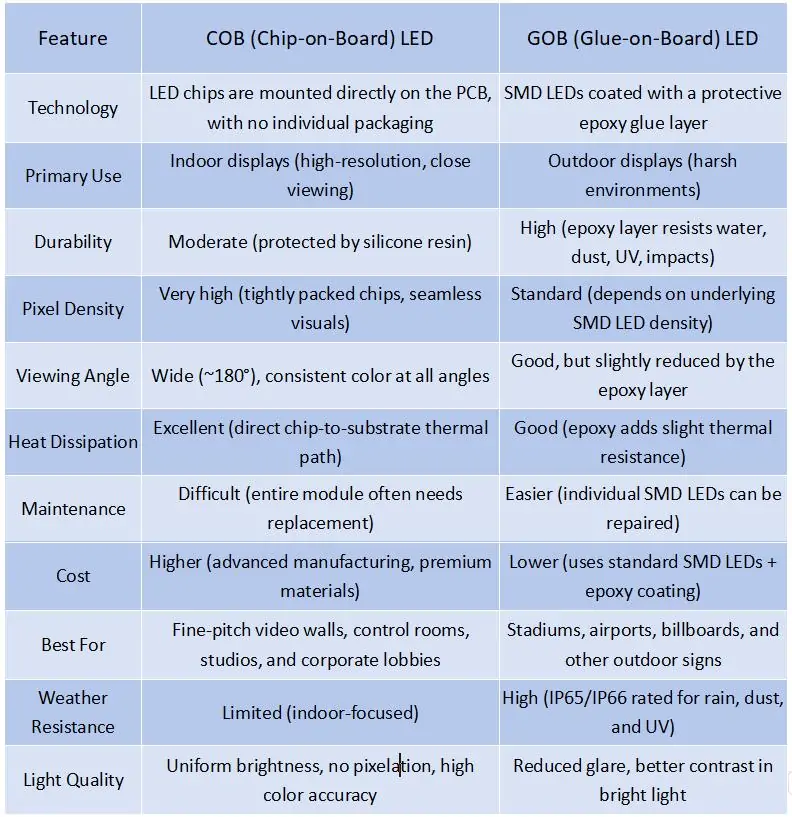

The previous sections provide a detailed breakdown of COB (ideal for indoor precision) and GOB LED displays (built for outdoor durability). Let’s compare COB and GOB across key aspects, differences, similarities, functions, and applications side by side, to help you decide which LED technology fits your requirements.

7.1 Key Differences Between COB & GOB

Different builds – Same goal: brighter, better business displays. Here’s how they differ.

7.2 COB Vs. GOB: Similarities

COB and GOB LEDs share a few similarities mentioned below:

- LED Technology: Both use LED chips for illumination.

- Brightness: Both COB and GOB are capable of high luminance output.

- Energy-efficient: Compared to conventional LEDs, COB and GOB LEDs are more energy-efficient.

- Protection Layer: Encapsulation (silicone resin) is used.

- Improved Reliability: Enhanced durability vs SMD LEDs.

- Modern Applications: Used in advanced display solutions.

- Thermal Management: Both have improved heat dissipation.

- Visual Performance: Better than conventional LED displays.

- Long Lifespan: 50,000+ hours typical lifespan.

- Market Adoption: Growing adoption in professional displays.

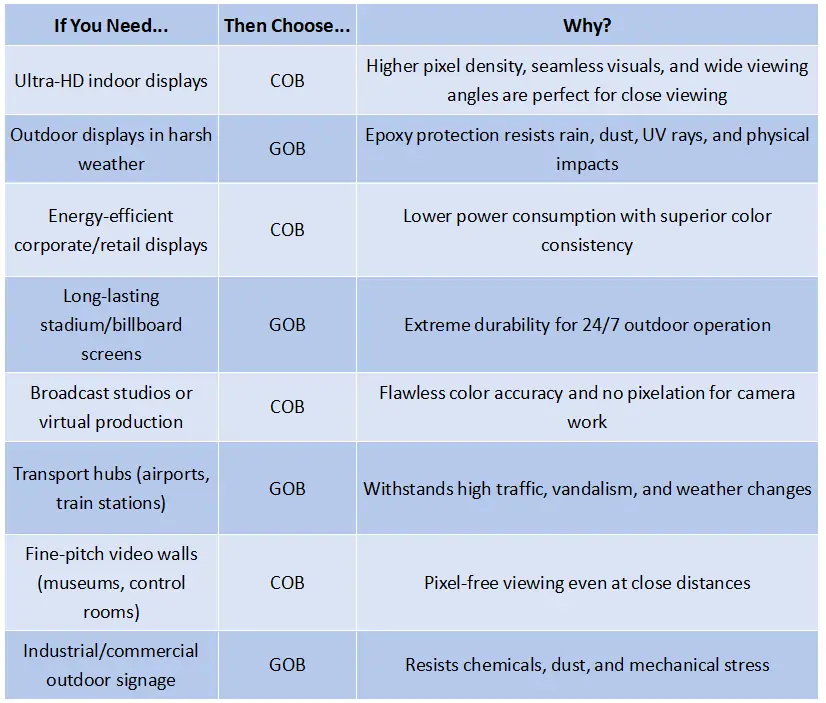

8. How To Choose COB Or GOB?

Whether for indoor or outdoor displays, businesses can guarantee optimum performance, durability, and visual quality by matching the appropriate LED technology to the application. Recognize what your project requires!

8.1 When To Choose COB?

Need ultra-HD, sharp visuals, and true-to-life color for indoor use? COB is the best option here with clean detail, stunning hues, and top-notch HD clarity providing outstanding visual quality.

Yes, it is more expensive at first, but its remarkable contrast and pixel density guarantee stunning images for intimate views and extended use.

8.2 When To Choose GOB?

GOB is a preferable choice if your project needs to be durable outside, move frequently, or withstand harsh environments, such as stadiums, transit hubs, or rental stages. Its epoxy coating offers strong defense against dust, rain, and impacts while preserving high-quality images at a more affordable cost.

Select GOB for durable, reasonably priced outdoor performance or COB for superior indoor aesthetics.

Below is a quick summary of LED display selection, providing highlights on when and why to choose the specific module:

9. COB Versus GOB: Key Considerations For Specific Requirements

Smart buyers benchmark beyond visuals. Assess operational constraints, environmental pressures, and service lifecycle.

Here is a structured guide to consider key factors while choosing COB and GOB modules for a specific requirement.

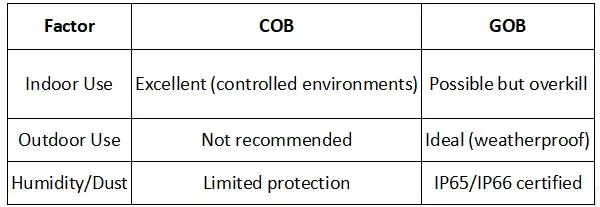

9.1 Environmental Requirements

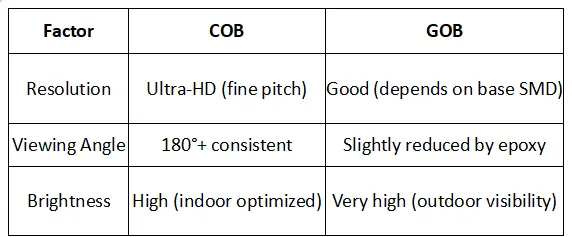

9.2 Visual Performance Needs

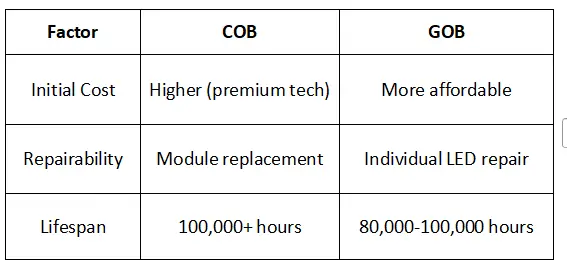

9.3 Budget & Maintenance

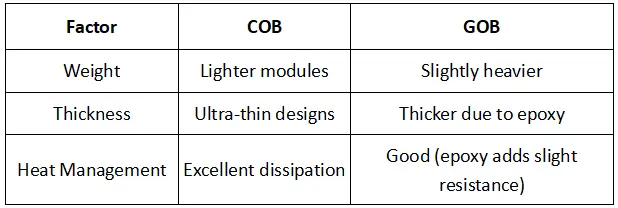

9.4 Installation Factors

10. Cost Analysis Of COB & GOB Displays:

Budget smart, not hard: Know exactly where your LED investment goes. The cost for GOB and COB LEDs is not fixed and varies with different factors. Here’s what drives the cost;

10.1 Cost Drivers for COB LEDs

- Mounting Structure: The Choice between standard mounting solutions or custom frames affects cost. For Example, Prefabricated wall mounts are less expensive than custom-made frames for specialized installations (such as suspended or curved designs).

- Chip Packaging Technology: When compared to SMD (used in regular GOB), COB raises production costs since it requires precision placement and wire bonding to connect LED chips directly to the substrate.

- Thermal Management: Due to the increased heat generated by COB’s dense LED arrays, active cooling or specialized heat sinks are required, which raises costs.

- Maintenance cost: Damaged COB LEDs are more difficult to repair and frequently need a complete module replacement, which raises the possible cost of maintenance.

- Manufacturing Scale: COB is less standardized than GOB/SMD, leading to higher per-unit costs in smaller production runs.

10.2 Cost Drivers for GOB LEDs

- Epoxy Encapsulation: The GOB process adds a protective epoxy layer over SMD LEDs, increasing material and labor costs versus non-GOB SMD displays.

- Dust/Moisture Resistance: While the epoxy coating raises initial costs, it reduces long-term failures in harsh environments (offsetting some maintenance expenses).

- Compatibility with SMD: GOB builds on traditional SMD technology, so it avoids some of COB’s complex bonding processes but still incurs encapsulation costs.

- Flexibility in Repairs: GOB allows individual LED replacement more easily than COB, potentially lowering servicing costs.

10.3 Additional Cost

Despite individual cost factors of COB and GOB, additional factors can significantly influence the overall cost.

Control System:

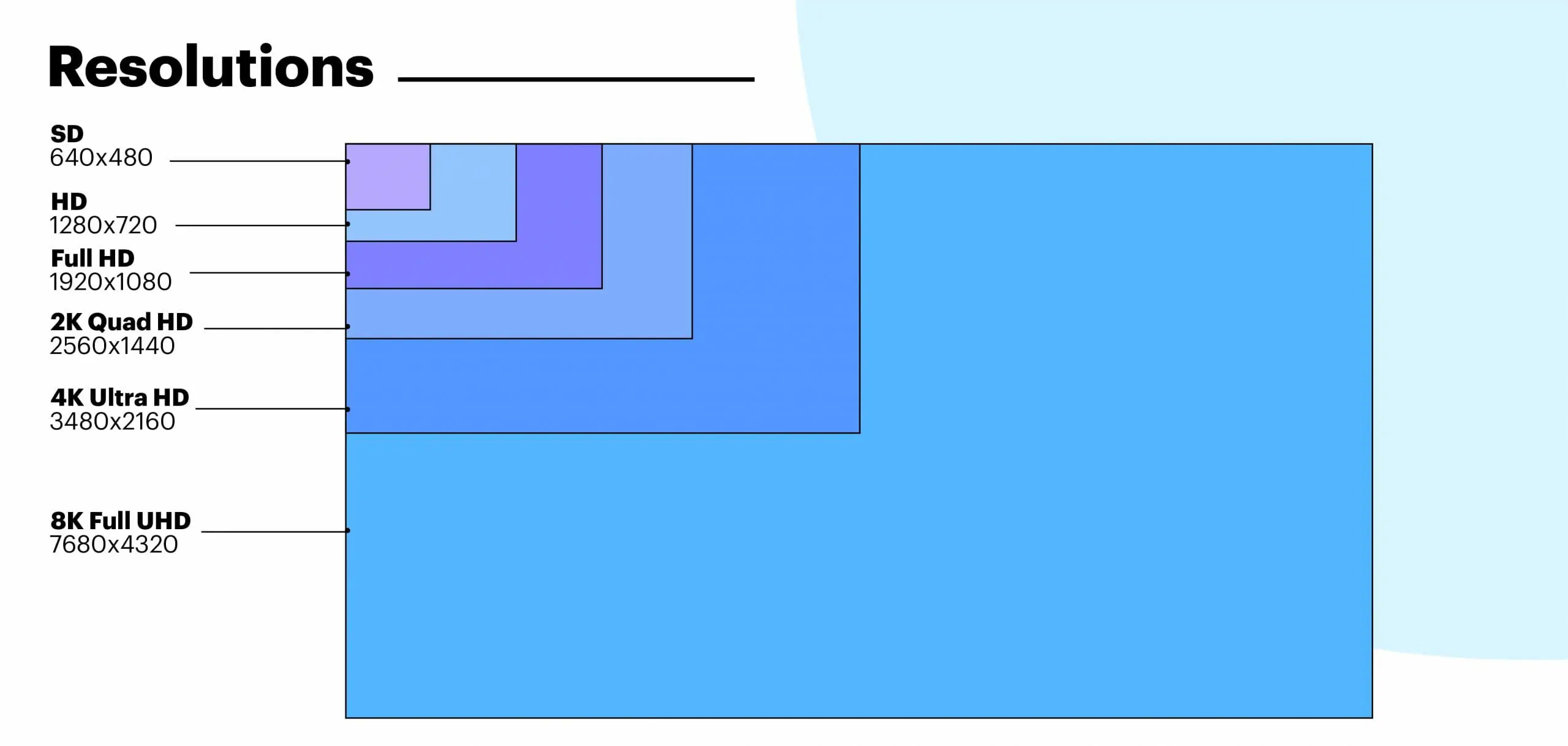

- Video Processor: Compared to basic HD systems, support for multiple inputs or greater resolutions (such as 4K or 8K) increases price.

- Advanced Features: The cost is increased by image scaling, HDR processing, or synchronization features.

Overall Project & Components:

The specific technical choices made for any component (panels, processor, software features, mounting, etc.) impact cost. Such as Integrating PCs, media players, cameras or adding remote control system increases system complexity and cost.

Vendor Supplying Components and Services: Different suppliers have different pricing structures for both hardware and services.

- Brand Tier: Premium manufacturers charge more for certified reliability and warranties than generic suppliers.

- OEM Services: Customized solutions (e.g., unique bezel designs or software) command price premiums over standard models.

11. How To Find Reliable LED Display Manufacturers?

Choosing a reliable manufacturer for LED displays guarantees their endurance, performance, and quality. Eagerled stands out as the leading LED display manufacturer in China. With 15 years of experience as an LED screen supplier, EagerLED specializes in indoor and outdoor rental LED signage, advertising LED billboard, transparent LED panel, HD LED video wall, and customized LED display board solutions to meet your business needs.

Whether you pursue the ultimate display effect of COB or prefer the ruggedness and reliability of GOB, EagerLED can provide you with professional and efficient LED display solutions.

12. Conclusion

Choosing COB or GOB LEDs involves more than selecting a screen; it’s about the strategic investment. COB and GOB LED displays are becoming the most advanced and popular LEDs in display technologies, serving different purposes. However, it’s essential to understand both technologies in detail to select the appropriate module.

GOB LEDs provide weatherproof resistance for tough outdoor situations (like stadiums), whereas COB LEDs offer greater resolution for inside precision displays (like studios). If you want pixel-perfect images indoors, go with COB; if durability outside is a priority, go with GOB.

Get a free consultation at EagerLED right now for any kind of LED display concerns.

Related Posts

Fill In Your Needs In Detail

Fill in the screen usage scene and size you need in “Content”.You will get a quote.