Features of LED Display Board

● 12mm stainless steel quick-lock design for fast installation

● Corner protector design and anti-collision base design

● Large-size positioning beads for fast positioning

● 3840Hz high refresh rate provides an excellent visual effect

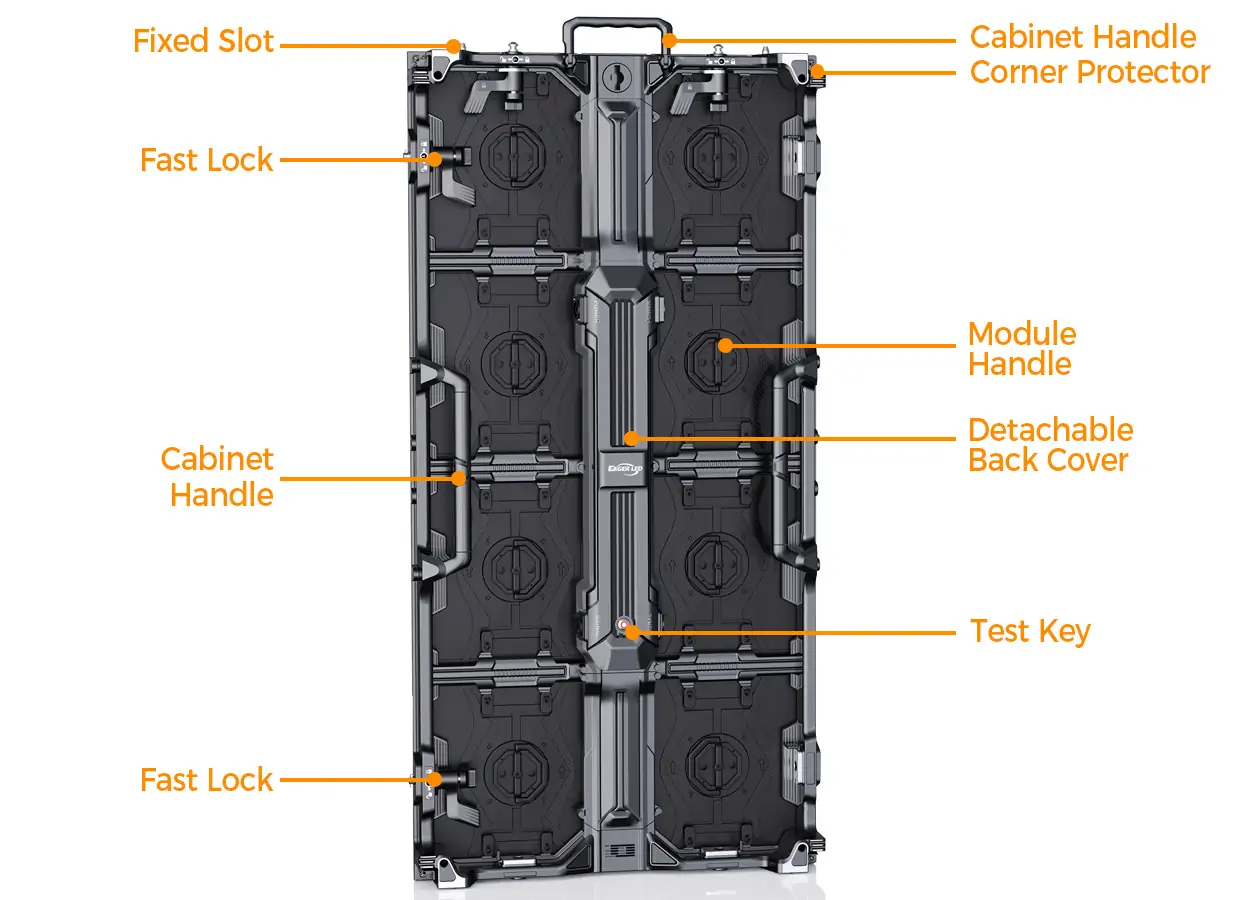

● With test button indicator for quick testing of the cabinet

● Door plate with heat dissipation design, conducive to box heat dissipation

● The tensile force of the LED cabinet is more than 1200KGF

● 140° wide viewing angle enlarges the visible range

Dual Service EA1000H9 LED Rental Wall

The standard size of EA1000H9 rental LED display screen is 500x1000mm, with arc locks, dual service design, corner guard design, openable power box and many other details designed to ensure the convenience of daily maintenance and enhance user experience.

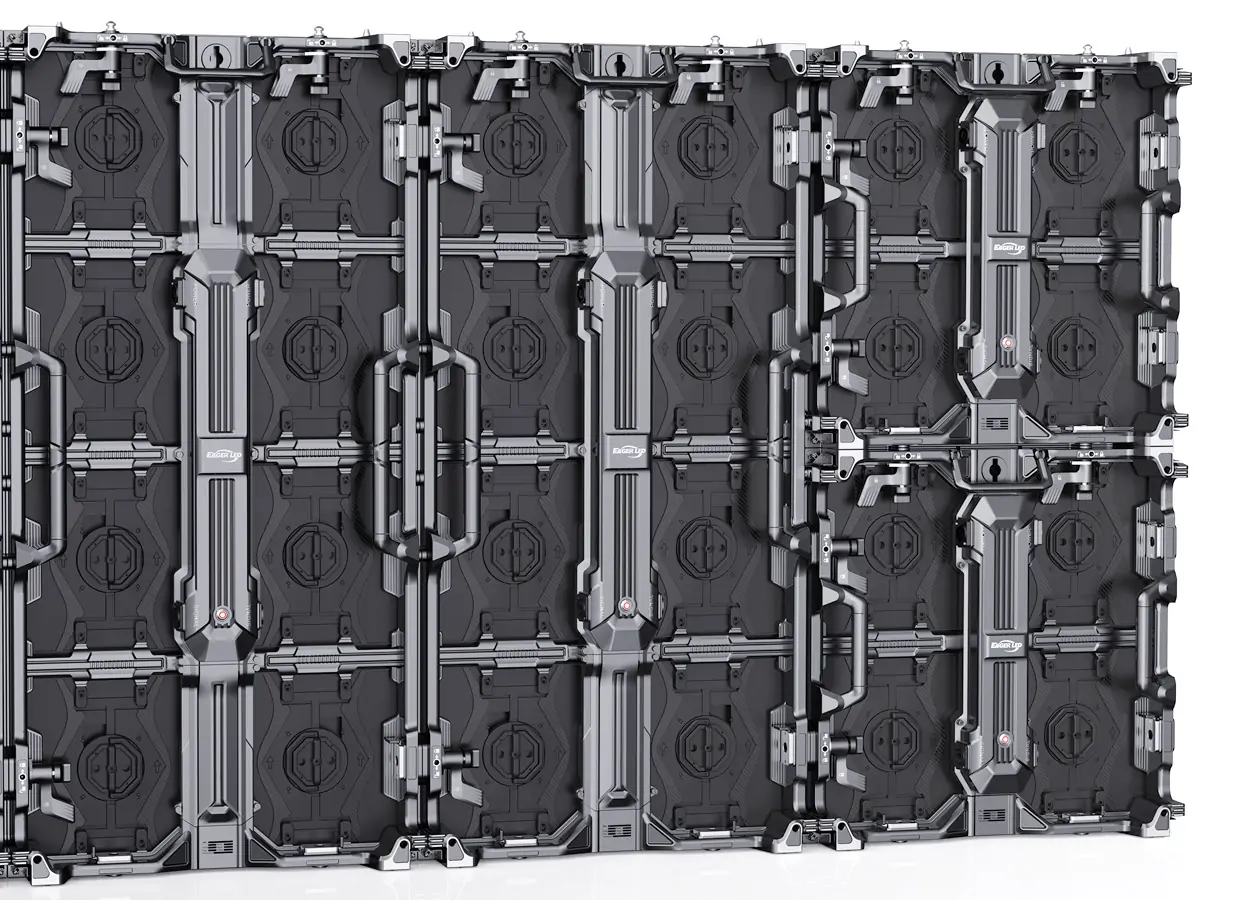

Perfect Cabinet Structure

EA1000H9 rental LED screen adopts quick locking and precise arc locking design to ensure the splicing is tight and firm, and also supports arc mounting. The hard connection design makes the cabinet look simple and beautiful. Humanized handle design makes it easy to move the box.

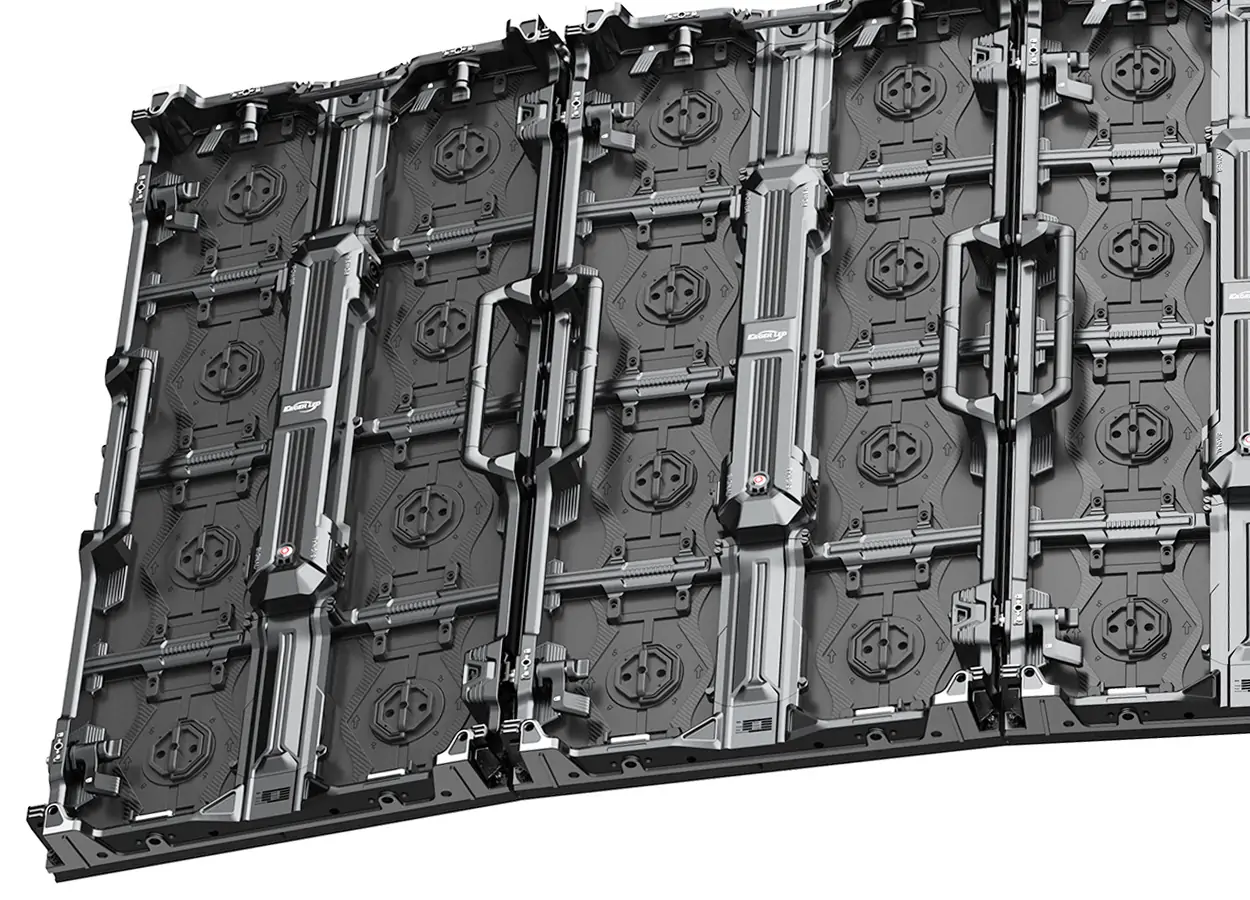

Arc Mounting (Optional)

EA1000H9 rental LED wall is equipped with adjustable high-precision curved latches that allow you to flexibly adjust the angle and design unique screen shapes for various setups.

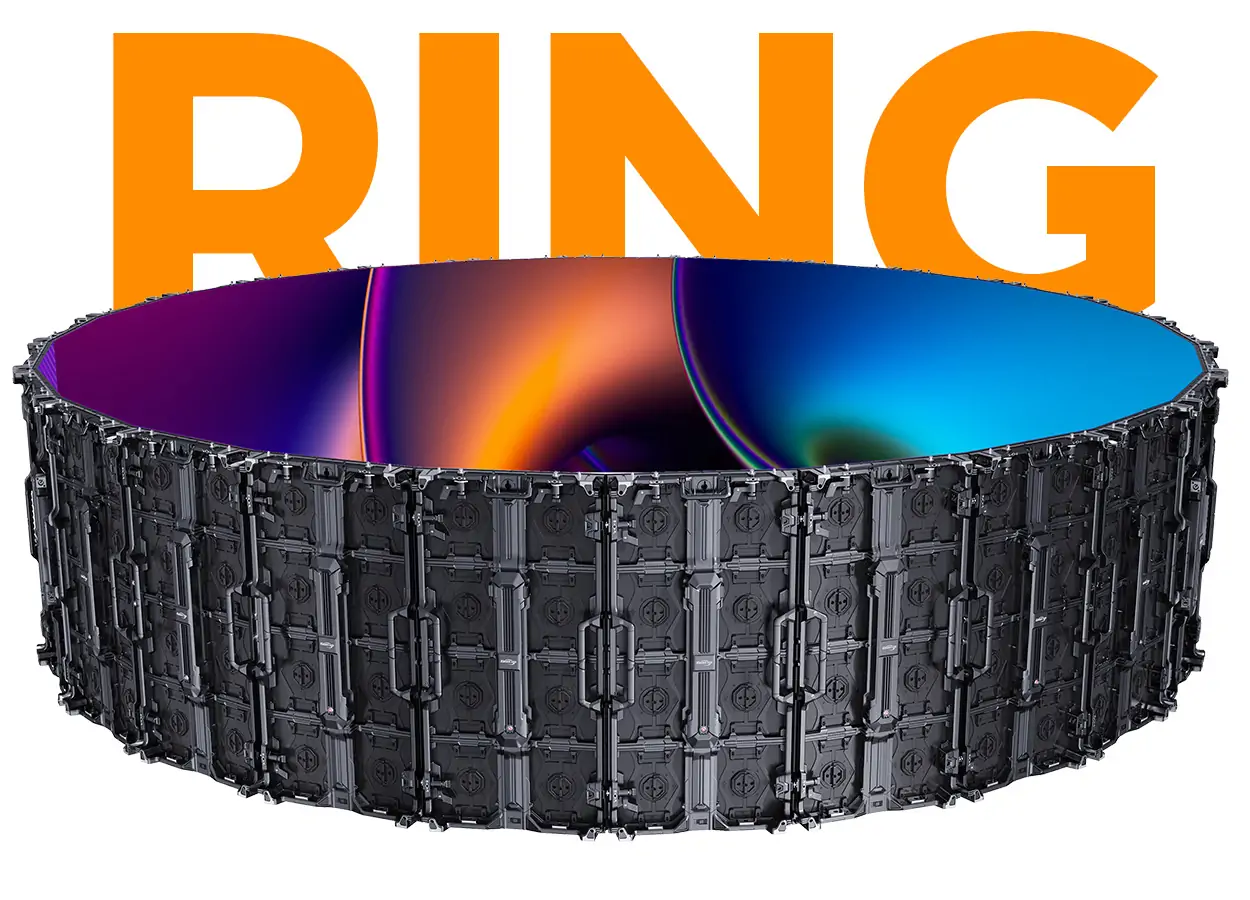

Circular Mounting (Optional)

High-precision curved latches allow you to easily install huge round LED screens. In addition, you can seamlessly splice LED displays into a variety of shapes to meet the needs of different scenarios.

EA500H9 Cabinet Assembly

EA1000H9 LED rental display is composed of EA500H9 cabinets with a standard size of 500x500mm. The fast lock design makes splicing more sealed without any visible gaps, maintaining visual integrity and video smoothness.

High Definition Display

EA1000H9 LED rental LED display screen has a high refresh rate of 3840Hz and a high 14-bit gray scale, providing viewers with better visual effects and high-definition images. The HD display effect can effectively attract customers’ attention.

140° Wide Viewing Angle

Vertical and horizontal viewing angles of up to 140° ensure that viewers can enjoy high-quality images no matter where they are on the screen, bringing an immersive visual experience.

Wide Range of Applications

EA1000H9 rental LED display screen is widely used in a variety of scenarios such as concerts, live events and exhibitions. The flexible and convenient installation design is perfect for temporary events and long-term use, and can meet various display needs.