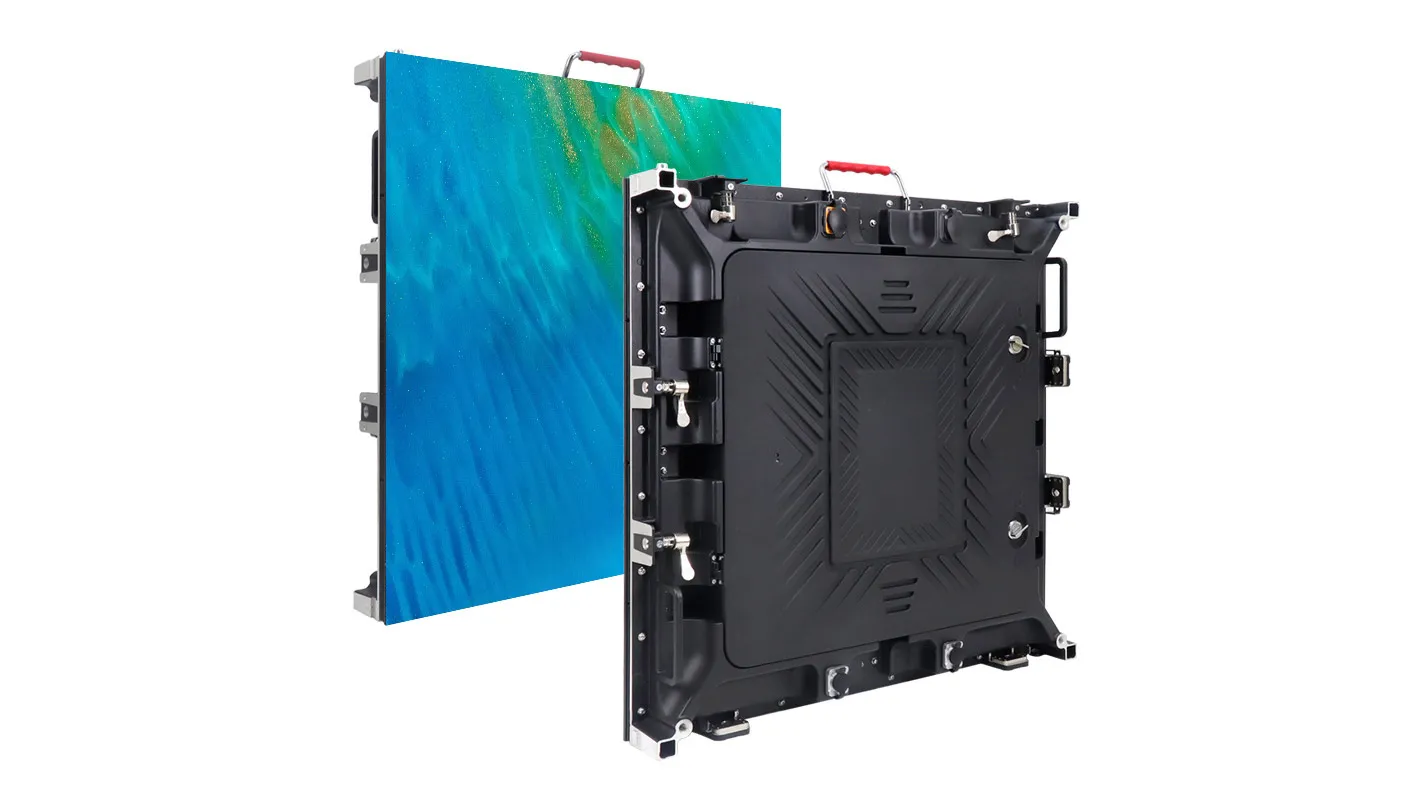

UV conformal coating, a type of protective coating, is a barrier against UV, dust, moisture, chemicals, and temperature extremes to provide efficacious protection for electronic assemblies and PCBs.

In this video, our workers place the LED module into the automatic spraying machine. Here are the main advantages of UV conformal coating.

(1)Rapid Curing: When exposed with UV light, the coatings will cure in seconds. This can reduce production time and increase the yield.

(2)Enhanced Protection: UV conformal coats provide superior protection from environmental elements, ensuring the performance and reliability of electronic components.

(3)Improved Adhesion: Their outstanding adhesive properties improve the durability of the protective coat, providing long-lasting protection against external threats.

(4)Flexible and Durable: UV conformal coatings have been designed to be flexible, and can accommodate thermal expansion and contraction without cracking.

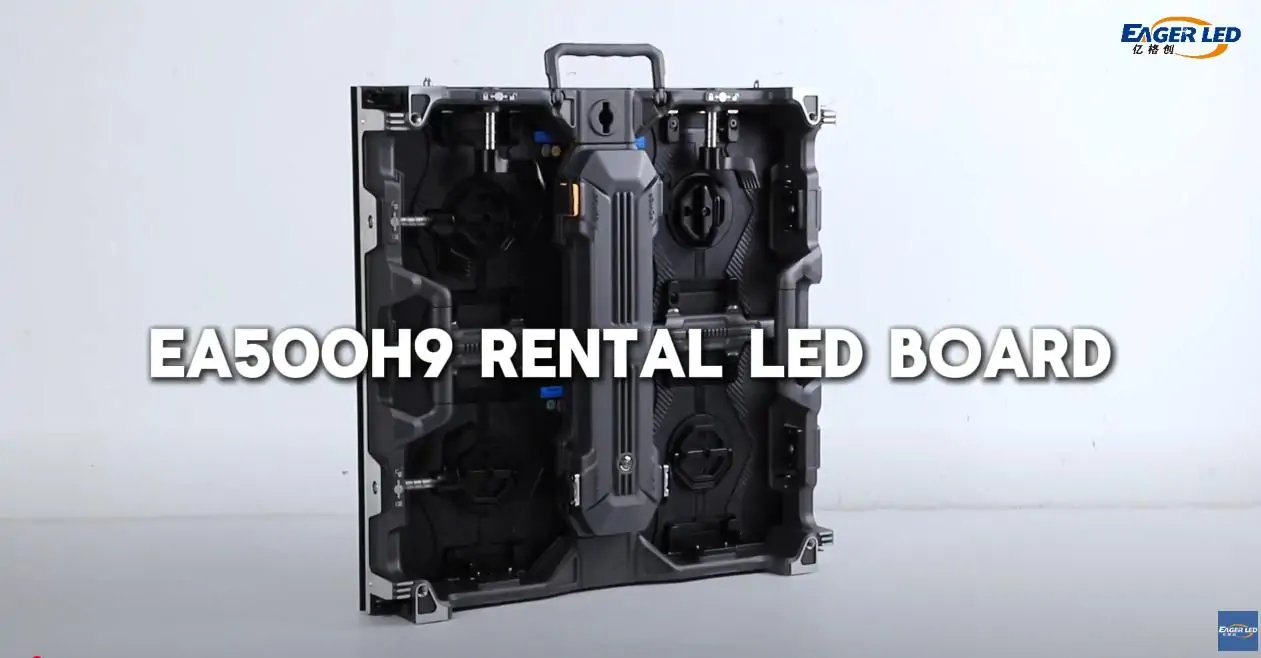

Our Eagerled LED module adopts UV conformal coatings designs to protect internal components and PCBs and greatly extend its service life.

Related Posts

Fill In Your Needs In Detail

Fill in the screen usage scene and size you need in “Content”.You will get a quote.