The quality control of LED display is a key step to ensure that the product meets high quality standards during the production process. EagerLED has adopted a series of strict quality management measures to ensure that each LED display is thoroughly inspected and tested before delivery to customers.

Before LED Screen Production

Before LED screen production

Before the LED display screen enters the production stage, EagerLED takes a series of key steps to ensure the reliability of product quality and performance.

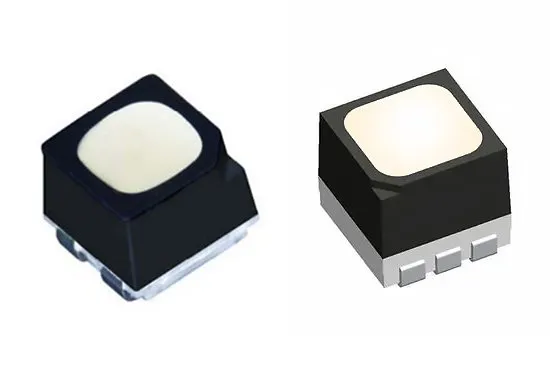

High-Quality Raw Materials

EagerLED strictly selects high-quality raw materials to ensure long-term stable operation and excellent visual effects of the product.

Professional Solution Provider

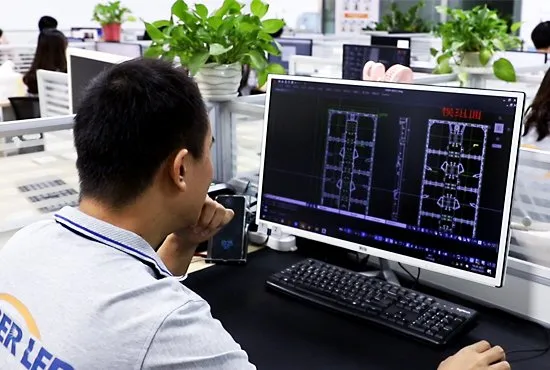

Before each project starts, EagerLED confirms the specific requirements and technical solutions of the LED display screen with the customer.

Production Process Check

Before production starts, EagerLED confirms every production detail with the production team to ensure that the production process is efficient and error-free.

LED Screen Module Production Process

LED screen panel production process

The module production stage of LED screens is a key quality control step. EagerLED uses advanced equipment and strict process flow to ensure that each step meets the highest standards.

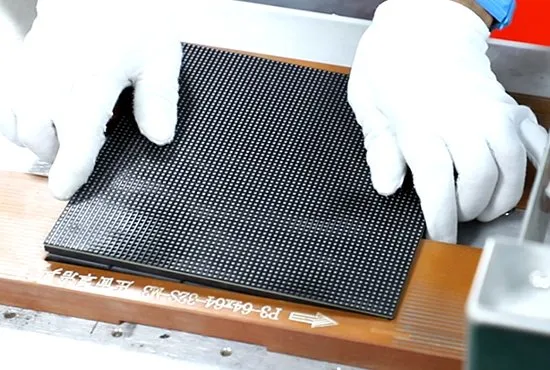

Dust-Free Production Workshop

Our LED screen production process is carried out in a dust-free environment to prevent dust and impurities from affecting the product.

Advanced Production Equipment

EagerLED has advanced production equipment and technical processes to ensure the precise manufacturing and assembly of LED displays.

Multiplex Testing

During the production process, LED display screens undergo multiple tests to ensure that the quality and performance of each screen module are at their best.

LED Module Lighting Test

Each LED module undergoes a lighting test after production to ensure that all LED pixels are working properly and there are no abnormal lamp beads.

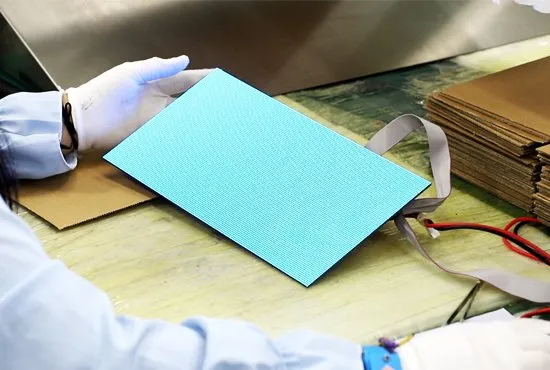

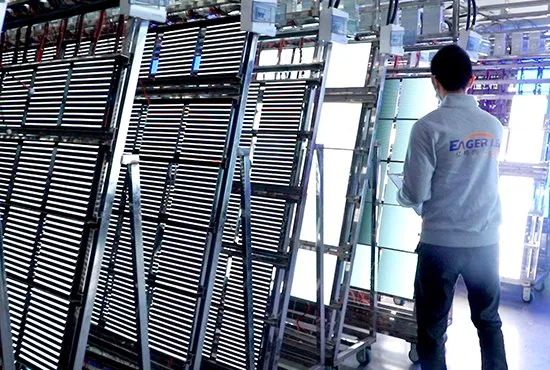

LED Module Aging Test

After the lighting test, the LED module needs to do a aging test in a simulated use environment to verify the stability of the LED module.

LED Screen Aging Test

The assembled LED screens do a comprehensive aging test to ensure that the product meets the highest quality standards before delivery to customers.

Product Package

After production is completed

EagerLED carries out strict packaging and shipping processes after product production is completed to ensure that the LED screen is not damaged during transportation.

Wooden Box

Large and heavy LED displays are usually packed in wooden boxes to provide additional protection and support to ensure that they are not affected by external shocks during transportation.

Air Box

For international transportation or projects that require fast delivery, EagerLED chooses air box packaging. This packaging method ensures that your LED screen arrives in time.

Through the above meticulous quality control process and strict inspection standards, EagerLED ensures that each LED display can achieve high quality and reliability to meet customers’ various application needs and expectations.

Get Quote Free

Get Quote Free

Want to learn more? Just send a message.